A fall protection inspection template is an essential tool for keeping your safety equipment – like harnesses, lanyards, and anchors – safe and ready to use.

By sticking to regular safety inspections, you help prevent accidents and stay compliant with safety regulations. Plus, using a checklist makes inspections faster, ensuring nothing gets overlooked.

For example, pre-use inspections give you a quick snapshot of your gear’s condition right before work begins. They’re faster than the more detailed checks you might do every few months, but still crucial for catching obvious wear and tear.

This documentation, aligned with safety protocols and enforced standards, also serves as proof of compliance when stored properly.

What Is Included in a Fall Protection Equipment Inspection Form?

When you’re checking your gear for fall protection, there are four main things to look for:

- Inspector identification: Who’s doing the inspection? It’s important to log the name.

- Equipment data: Record the manufacturer and serial number of the equipment being checked.

- Equipment defects: Identify any damage or wear and tear that could affect safety.

- Readiness for service: Is the equipment safe to use, or does it need repair or replacement?

These details ensure that each piece of equipment is inspected properly and ready to go. The goal is to catch problems early – sometimes equipment might show signs of wear but is still usable for now. It’s crucial to know the difference.

Why It’s Better to Use a Digital Fall Protection Inspection Template

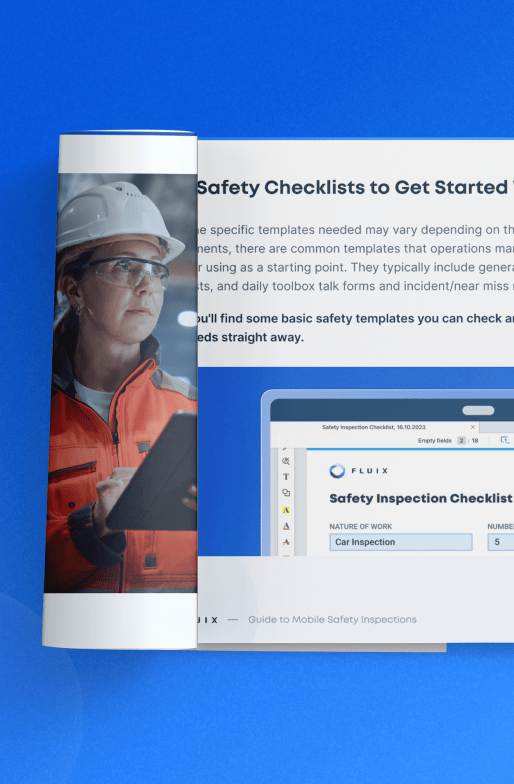

Now, imagine the ease of doing all your inspections digitally. Digitized safety documents don’t just save you time – they ensure nothing gets missed. They can prompt workers to complete all the required fields, flag incomplete forms, and provide real-time updates.

Let’s be honest – fall protection and paper don’t mix, especially when working at heights. Paper forms can get lost, damaged, or incomplete. Switching to digital ensures your inspections are thorough and convenient, boosting both safety and productivity.

With safety inspection solutions like Fluix, you can transform these forms into efficient workflows that standardize safety practices across your entire team. And offline access can allow workers to complete inspections remotely, even without an internet connection.

Whether you’re on-site or in a remote location, you can manage everything on your device, keeping your team safe and compliant no matter where they are.

The Ultimate Guide

to Safety Inspections

Checklists, tools, and best practices to help you meet the safety regulations for your industry and don’t risk fines

How Fluix Can Help Manage Fall Protection Checklists

Fluix is field productivity software that can simplify your entire fall protection checklist process, helping you stay compliant and keep your team safe. Here’s how:

- Ready-to-Use Template Library: Get started right away with Fluix’s library of customizable fall protection templates. No need to build from scratch – you can easily adjust templates to fit your specific needs.

- Form Builder: Want something custom? Our drag-and-drop form builder lets you create your own custom checklists in minutes. Add fields for equipment data, inspector details, or anything else your process requires.

- Mobile Accessibility: Your team can complete inspections on any mobile device, making it easy to stay on top of safety, even when they’re out in the field.

- Offline Data Collection: No signal? No problem. Fluix allows workers to fill out forms offline, and all data syncs automatically when they’re back online. This is perfect for remote sites or areas with limited connectivity.

- Photo Documentation: Want a clear visual record of your equipment? Our app lets your team add photos directly to checklists, providing extra proof that equipment is in good condition – or capturing any wear and tear.

By digitizing and automating your fall protection checklists, Fluix ensures no step gets missed, saving you time and boosting field productivity.