The construction industry faces various challenges. The main issues though are still related to safety of construction workers at the construction site and the lack of communication between offices and frontline workers.

But there is a way out: implementing QR codes and barcode technology proved to make it all better. Let’s go through all the arguments to their advantage.

First and Foremost: How QR Code Can be Used?

The construction industry needs to have a possibility to maintain accurate training records, safety management regulations, asset records, and other important documentation up to date, and in order.

Changed the sticker? This should be recorded in a vehicle control inspection checklist. Found an error? — Notify the team. QR code technology allows this information to be accessed very quickly, making it more efficient for people on site, whether it’s to find a floor plan or to visualize the building in 3D somewhere in the middle of the site.

To understand what tasks you can solve at the construction site by implementing the technology of QR codes, let’s look at 7 examples.

Task #1. Verification of construction site staff.

There’s a lack of real-time knowledge about the skills and qualifications of the construction staff for admission to work on site. To solve this problem, there are datasets that summarize and make clear information about each employee. Every piece of important information is listed in a sheet.

A unique QR code is created containing information about a particular construction worker. This code is usually duplicated on the helmet or tag of the worker. After scanning the QR code with a smartphone or tablet, the information about an employee will be displayed on the screen.

Usually such identifying information includes the following bullet points:

- name of the structure;

- name of the structural part of the building;

- level and assembly;

- the company for which the employee works;

- information about the equipment with which the employee works.

Task #2. Equipment shipping.

By placing a QR code label on or near a technical item or workpiece, any worker can display all the information contained in a particular form on their smartphone or tablet. This allows the engineer and construction worker to better understand the construction processes taking place at the site.

Task #3. Safety talks made simple.

It’s common for construction companies to have documents describing special operating procedures such as operational safety plans or toolbox talks. These documents usually have a specific lexicon. Thus, they are not suitable for practical use on construction sites. Well, this is a pickle, but it can be overcome. What you should do is to attach a QR code to each of the forms of these documents that redirects to a web page describing the procedure.

Task #4. Incident reports.

No one is immune to incidents. Someone stumbles, someone falls. At that moment, every moment counts. Imagine if you had to fill out a piece of paper instead of helping a person. Creepy, right? The speed of your response at the scene is often dictated by how and where your information is stored.

Perhaps your emergency contact information is in a file cabinet in a construction trailer or locked in a spreadsheet in your home office. Now imagine if you could just scan a QR code and access your emergency report in a second, and just as quickly notify another part of the team wherever you are.

Task #5. Making drawings all-readable.

Since market demand for new buildings always follows demographic trends and stays in tune with economic conditions, designs and plans can be changing over the course of construction. It can be difficult to keep track of layout changes, updated schedules, material checklists, and MEP drawings.

Thus, it is important for the parties involved not to make any mistake, because the potential cost of failure would outweigh the expected benefits. Using QR codes on engineering drawings, punch lists, and inspections, you can help communicate updated layouts and schematic drawings.

Expert advice: To increase site efficiency and minimize errors, it is practiced to scan these QR codes daily to alert contractors and workers of changes made.

Task #6. Job-site check-in.

Place QR codes at the gateway in a fixed location on the site so the construction crew can check in on their presence as well as access plans and schedules. Attach QR codes to keep track of payoffs and daily work tasks. Make use of QR codes that can lead to a checklist sheet to record daily moves, upload photo documentation, and fill out daily tasks.

Task #7. Instruction manuals.

Most equipment does not have a handy manual with simple instructions. QR codes on product packaging may contain a link to a web page or video explaining how to install and use the product.

More on the Topic: How to Fill Out a Mobile Form

Why Do Businesses Use Barcode Scanning?

The facts say that the barcode was invented in 1951, but is still in use today. Any organization, distributor, wholesaler, reseller, or construction industry in the trading world is familiar with barcode scanning technology.

And no wonder why: those little striped squares have become so widespread in our modern world that there are countless inexpensive ways for any business to take advantage of the barcode scanning system.

Well, let’s get right to the point — what are the benefits?

#1. Barcodes eliminate errors

It is human to err, and almost no one knows that better than the construction industry. Now try to extrapolate this to entire systems: shipping, receiving, buying, and selling billions of dollars worth of equipment. It would not just be ‘a certain amount of mistakes’, it would be a disaster.

Barcodes help prevent such things by systematically collecting and tracking equipment data.

Remember that barcodes store and transmit only the data you decide to store in them. If you want to track each kind of your equipment separately, you will need different codes.

#2. Barcodes are inexpensive

Barcodes are cheap. The technology has been around for more than half a century and is very inexpensive. Barcode scanners are inexpensive (no more than $75 for a great scanner) and are used worldwide as the gold standard for scanning goods.

#3. Barcodes saves costs

The moment you can hand over a human task to technology, you’ll save time, reduce errors, and thus costs. Here is an LUDWIG FREYTAG Case Study: Founded in Germany in 1891, LUDWIG FREYTAG, a broad-based network of fourteen construction companies provided their technicians with barcode scanning technology. Their technicians have no need to work on files manually and type anything on equipment shipment documents. They just scan the inventory number, which, for sure, saves many of their working hours.

A reliable barcoding system consists of three main parts:

- A method of producing and printing barcodes

- Scanner for barcode decoding

- A platform for receiving decoded barcode data

Barcode & QR Code Mobile App

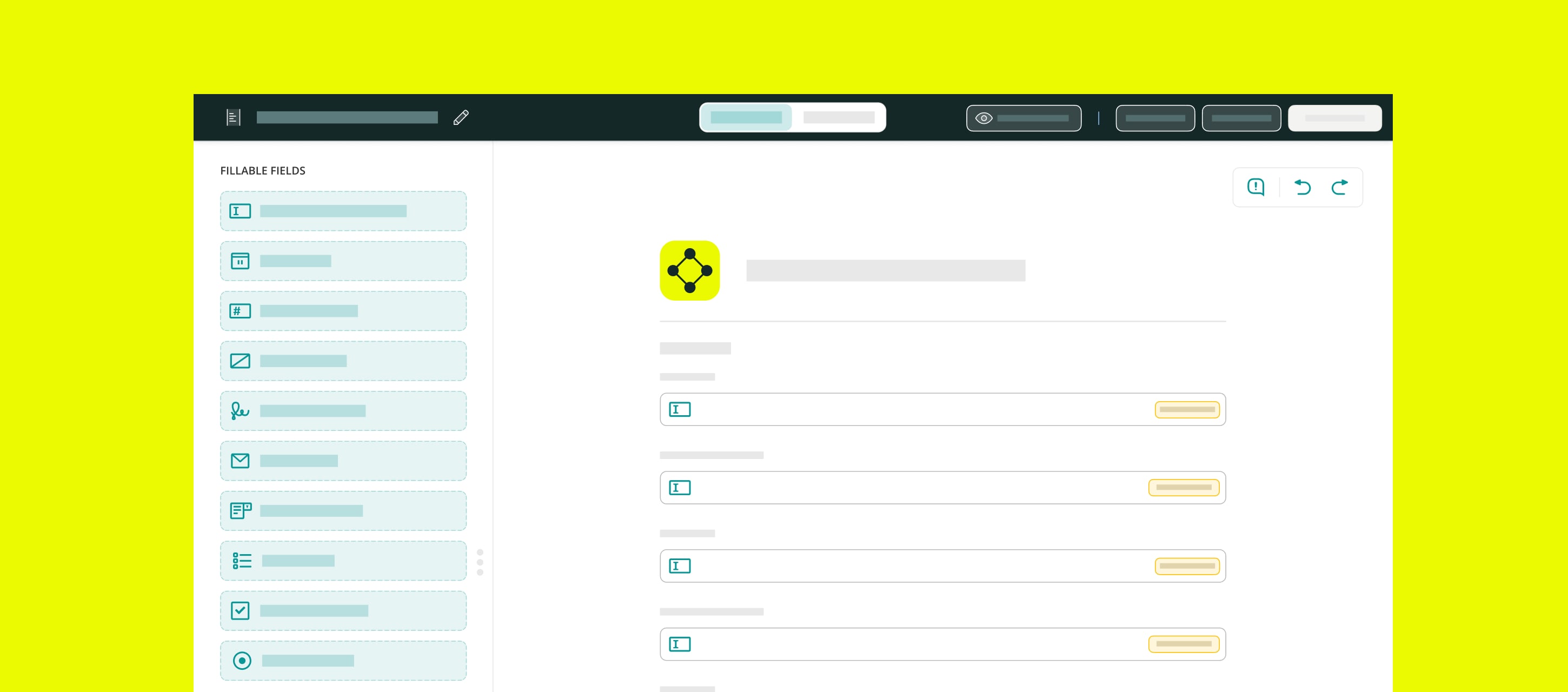

As you may agree, standing on top of a turbine in the rain, snow, or being at a construction site in rubber gloves, you least want to look in your pocket for a pen to fill out a paper form. As mentioned above, it would be more convenient to scan the QR or barcode. It’s even better if you don’t have to switch between your construction site software.

That’s why one of the advantages of Fluix is that it is possible to scan the QR and barcode from the form itself without leaving the application. This means you can fill out forms about the status of your construction tools and equipment between job sites, trucks and tool storage in real time. You will always know where the tools and equipment are, how long they have been used for each project, and how efficiently the equipment and tools are being used.

Expert Advice: If you work in a dirty or hostile work environment, consider investing in rugged barcode labels. The metallic etched labels and metallic foil labels withstand rain, dirt and scratches much better than traditional barcodes.