1. What Is a Construction Workflow?

A construction workflow refers to the orderly series of tasks and actions your team must complete during a construction project. A well-documented workflow outlines the process from beginning to end, including the planning stage and post-project documentation.

Workflows make it easy to establish the who, what, where, when, and how of each aspect of a project. They provide a clear order for doing everything on the job site.

It is a good practice to create a separate workflow for every project and task. By adjusting flows to different processes, such as site preparation, foundation work, or interior finishing, you ensure that tasks are performed in the most logical and efficient order.

This reduces downtime, avoids redundancy, and minimizes the risk of missed steps, leading to faster project completion.

2. Construction Workflow Formats

As you create workflows, you can utilize different formats, for example, flowcharts, bar charts, checklists, kanban boards, etc.

You’ll also discover various methodologies for executing construction workflow processes, such as:

- Waterfall: This traditional project management method involves a structured sequence of events that flow one after the other. While it provides excellent visibility into a project and order, it can struggle to accommodate unexpected changes.

- Agile: The agile methodology is all about flexibility and breaks up projects into small parts. Instead of sticking to a set order of operations, you can adapt or revise steps in real time to deal with changes.

- Lean: Lean construction management puts the focus on eliminating inefficiencies and waste. You can achieve this by paying close attention to the supply chain to avoid breaks in production.

Often, there is no one-size-fits-all solution. Careful reviews of past projects is useful to determine which methodology or combination works best on a project.

Trading manual labor for automation is also an attractive deal. This is where construction workflow management software like Fluix can help with design and management of your workflows.

3. Benefits of Construction Workflows

After going digital with your construction business and creating a truly efficient workflow process, you can expect the following benefits.

Pre-Construction

Effective workflows make certain that your team completes tasks in a logical and safe order. As a result, you’ll get the project done right the first time and have less rework. You’ll also prevent slip-ups that lead to costly accidents.

Consistent Systems for Repeatable Success

Your team will get more comfortable and faster at doing jobs when they have a consistent process for repetitive tasks. Even when you need to make slight adjustments, everyone will be more efficient because they won’t be wasting brain power on figuring out how to do things in a completely new way.

Without a preset construction workflow, successful project completion will be a moving target. Using workflows, you have a replicable system for guaranteeing high-quality work for customers and a safe workspace for employees and contractors.

Better Time Management

As workers become comfortable with your workflows, they need less supervision and explanations. That leaves you and other supervisors more time to dedicate to other construction management issues.

Enhanced Teamwork and Communication

Efficient workflows boost team morale and improve how well crews collaborate on the construction site. Everyone knows their role and project timing. This reduces time-wasting disagreements and disputes.

Cost Savings and Budget Management

This smooth and transparent work process ultimately results in cost savings and increased revenue because you don’t lose money on wasted time or resources. Improved worker safety means dealing with fewer injuries or preventing them altogether. Finally, your customers will be happier, preventing unnecessary contract terminations.

Transform Your Construction Workflows:

Start Automating Today with Fluix

4. Examples of Most Common Construction Workflows

Each of the following areas benefits from having a fixed workflow template.

Submittal Workflow

Construction submittals are key to approving subcontractor work and ensuring quality. Make sure you have a clear construction workflow for submittals.

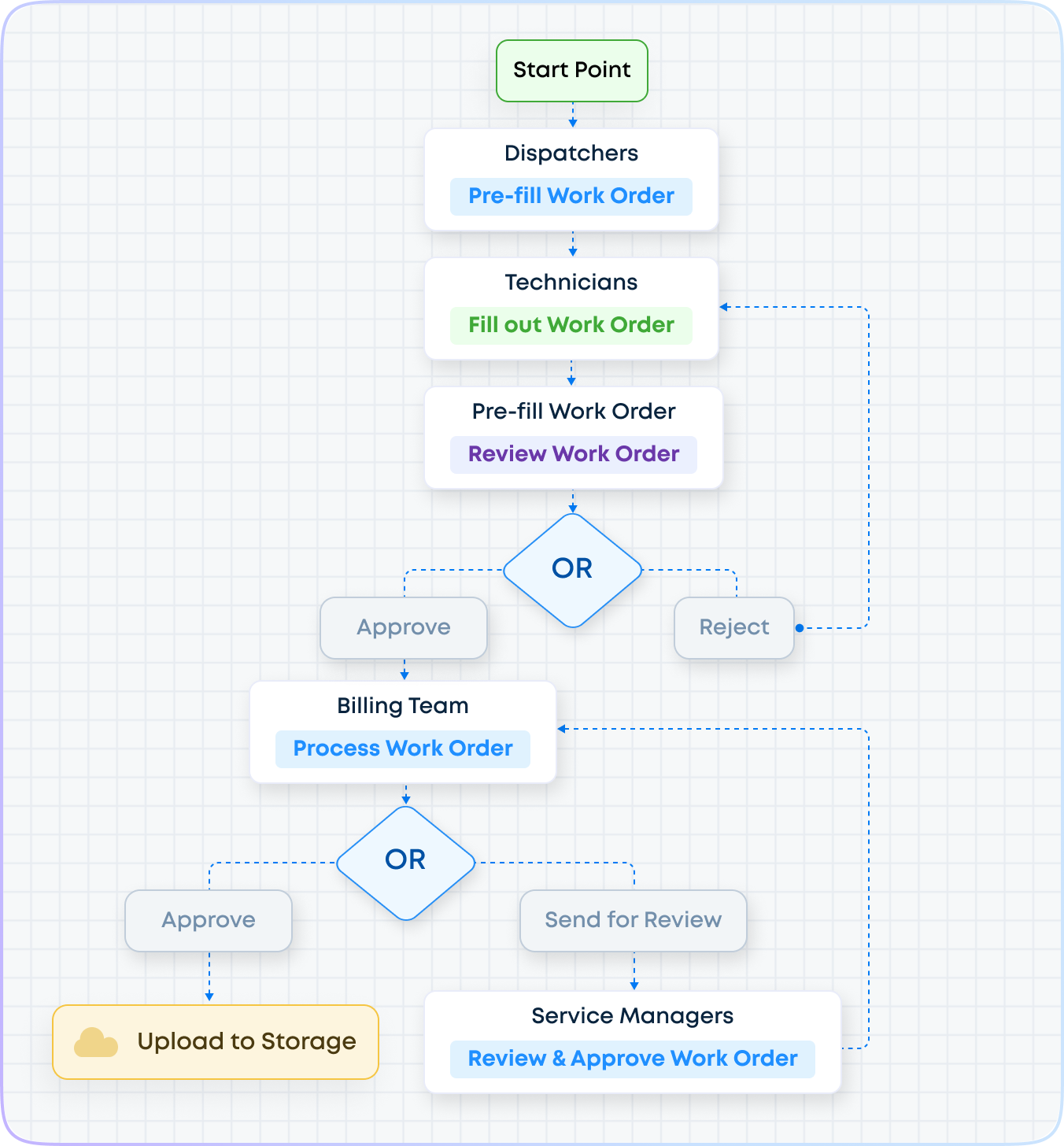

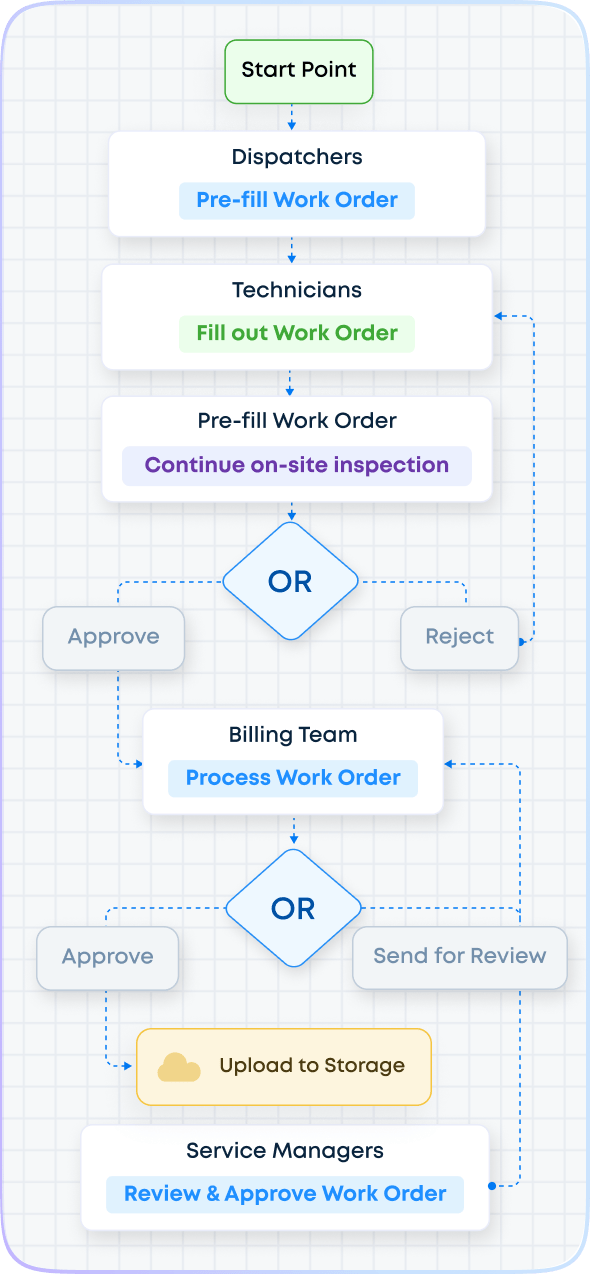

Work Order Workflow

Requests for maintenance, repair, or operational work can come from any number of sources. Unfortunately, it’s easy for these to get lost or pushed to the back burner until a problem escalates. Workflows simplify approval, scheduling, and closure.

Risk Assessment Workflow

Risk management in construction is critical but doesn’t have to eat up an inordinate amount of your time. Use a risk assessment management method statement (RAMS) template and a workflow to promptly assess risk, as well as the control measures and emergency procedures.

Procurement Workflow

Supply chain issues persist in the industry, so isolating a flexible procurement workflow is key to preventing bottlenecks. You can more easily coordinate between departments about project budget availability and timelines to expedite the approval process.

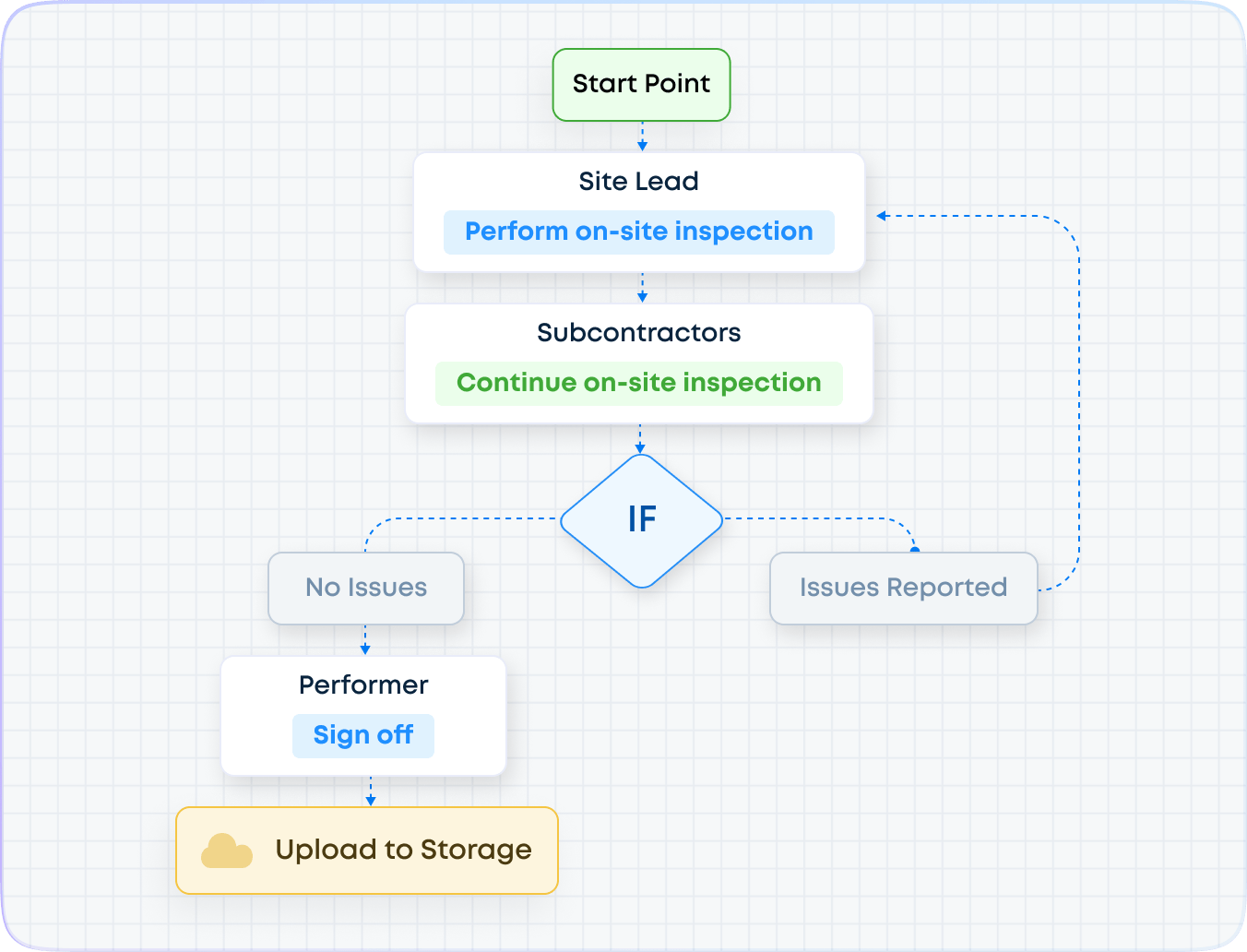

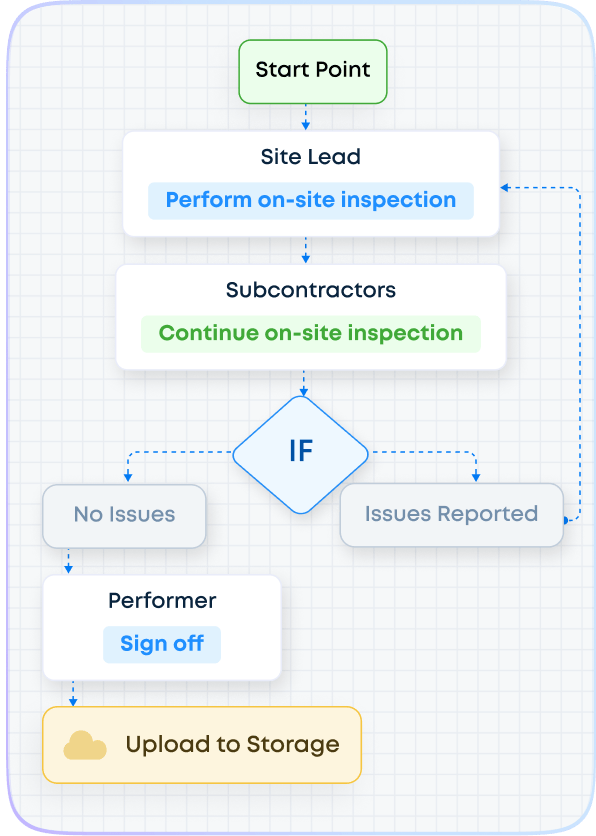

Commissioning Workflow

The commissioning process is the set of procedures you use to ensure equipment and systems satisfy regulations and project requirements.

With a flowchart, all specialists who take part in this process will know how and when to fulfill their role. You’ll be able to get the job done fast while maintaining strict quality standards.

There are many other construction workflows you can implement, including:

- Change management

- Pre-construction

- Closeout and turnover

- Requests of information (RFIs)

If you need digital assistance with any of the above processes, Fluix can provide it. From site inspection to onboarding, you can digitize any processes, improve collaboration among teams, and ensure that every step in your workflow is executed efficiently.

To cover the key aspects of the process, we recommend using these checklists:

5. How to Manage Construction Workflows Effectively

Your workflows are only as good as your system for managing them. This means overcoming a few challenges.

For example, the appropriate teammates need to be able to easily access information and update task details. At the same time, you don’t want just anyone to be able to alter templates or essential items.

Unfortunately, document and file-sharing systems don’t always make it easy to manage permissions for workflows. While project management software is great for overall concerns, it often lacks the elements necessary for managing specific construction workflows.

Therefore, your team benefits from having construction field management software that can integrate with your project management software to specifically help you create tailored workflows and update those as necessary. Such a system provides a single resource that everyone can use in real time, whether in the office or the field.

As you choose software, make sure it has the following features:

- Standardization: Eliminate redundant work or avoidable risk by standardizing your workflows with editable and easy-to-access templates.

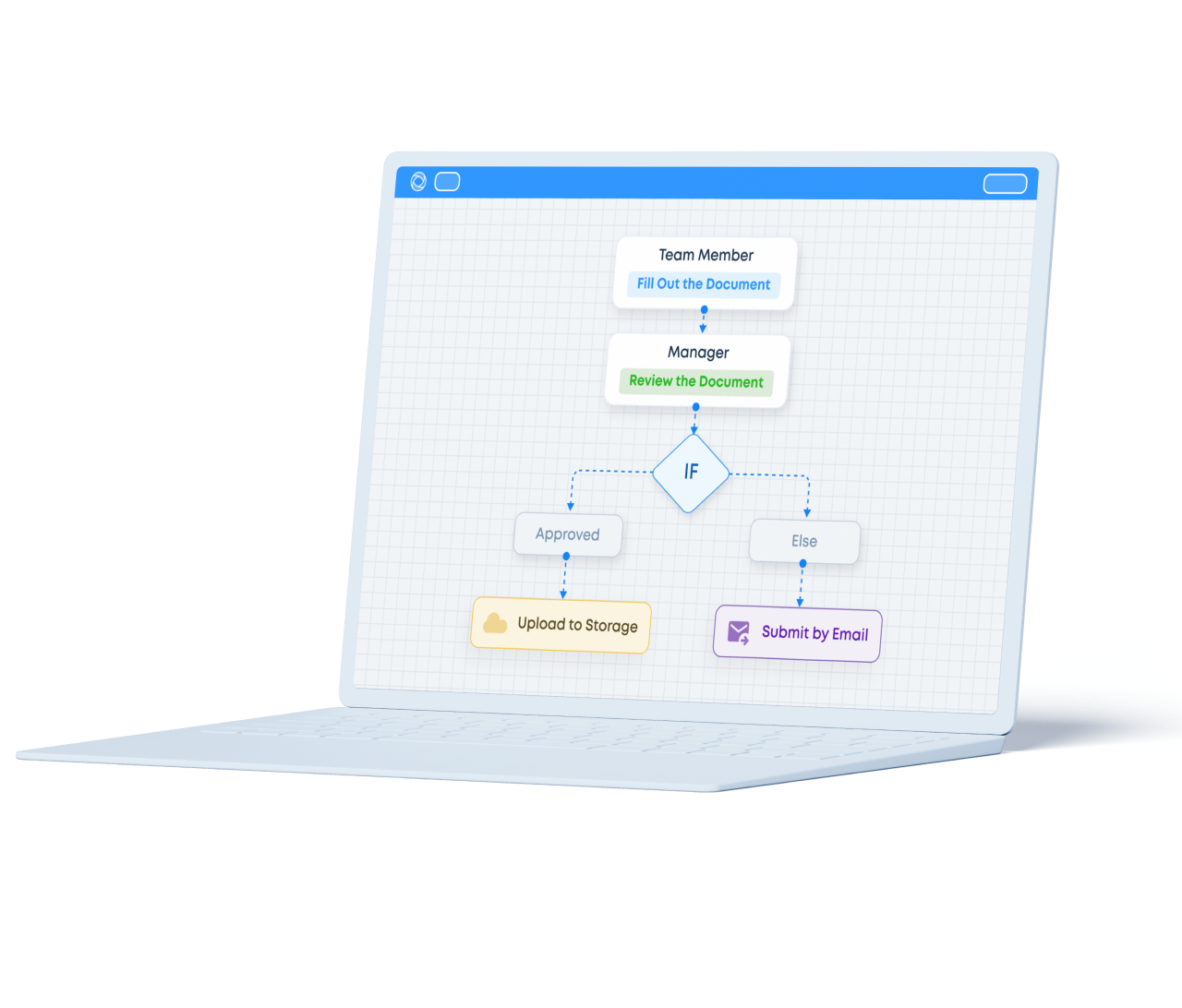

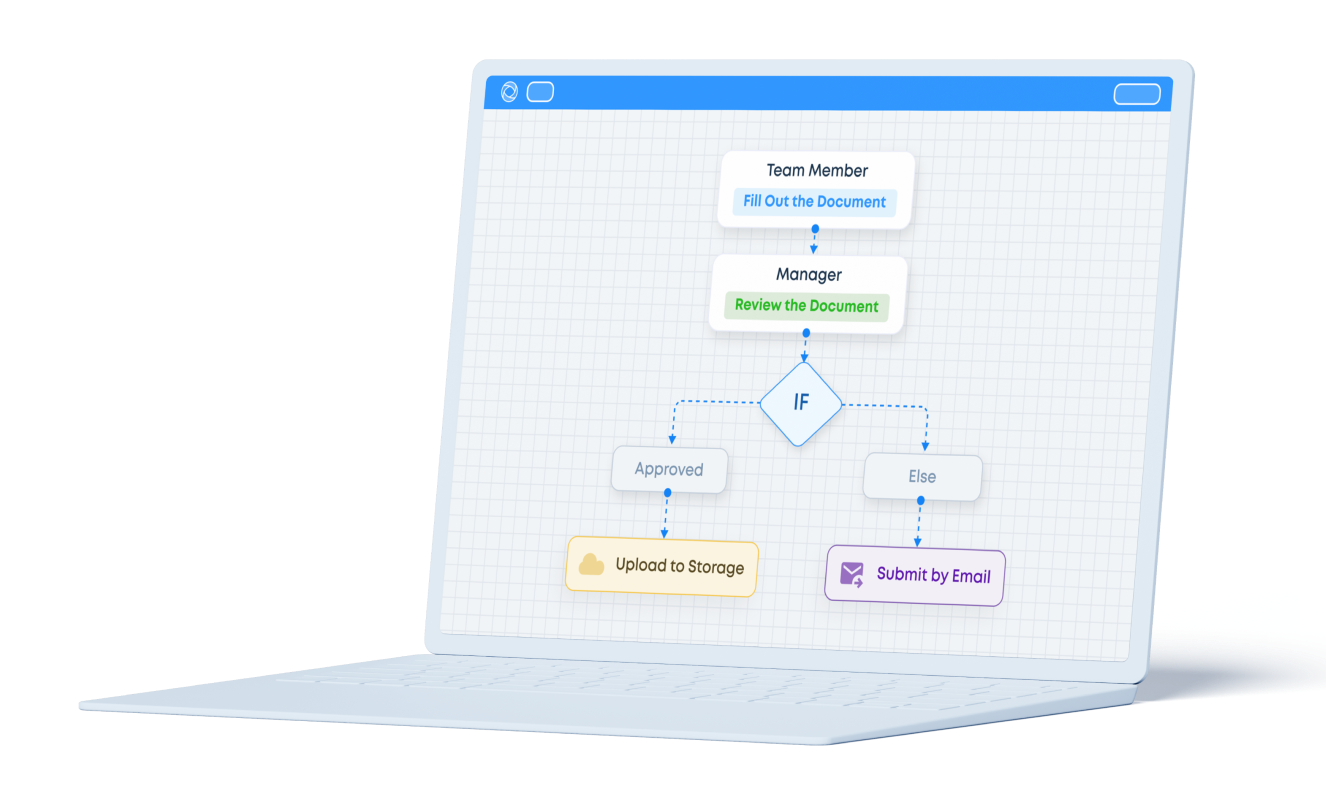

- Automation: Besides automating the process of creating and checking for errors in your finished workflows, you can quickly notify the right individual when an item requires action or approval.

- Collaboration: Workers should have access to real-time statuses and updates with mobile apps they can use in the field.

- Integrations: Integrations with your other platforms speed up data collection and entry for greater efficiency and reduced errors.

Building More Efficient Construction Workflows with Fluix

Manual workflow admin is often inefficient, poorly organized, and full of delays. A simple solution to this inefficiency is using digital tools like Fluix.

This workflow automation software has the necessary tools for document management, task assignment, communications, and reporting, including:

- Digital checklists

- Automated approvals

- Notifications and alerts

- Task assignment and progress tracking

- Integrations with Procore, Power BI, and other tools

- Cloud storage

If you’re new to automation, our team can guide you through the process of setting up workflows, customizing them to suit your specific needs, and ensure your transition to a more efficient, automated system is as smooth as possible.