Work order management often feels more complicated than it needs to be. But with the right tools in place, it can become a streamlined and efficient process, cutting down on downtime and confusion.

Want to learn how to take control of your work orders? Check out our detailed guide.

Contents:

What Is Work Order Management?

Work order management is a process for handling service or maintenance tasks from the moment a request comes in to the moment the job is done and documented. It involves creating a formal work order, assigning it to the right team, tracking progress, and closing it once the task is complete.

It plays a focused role inside the bigger field service management picture. While the latter keeps the whole operation moving (for example, dispatching teams, scheduling jobs, managing resources), work order management focuses on the details of each task.

Let’s say your team is dispatched to fix a faulty generator. Work order management ensures they know what to do when they arrive, what parts to use, and what to document before leaving the site.

READ MORE: 10 best Fieldwire alternatives for efficient work management

Why Work Order Management Is Important

Efficient work order management is crucial for operational continuity and safety. Here’s why:

- It improves efficiency. A solid system helps you prioritize jobs, assign them fast, and keep things moving..

- It strengthens communication. When everyone’s working from one central system, updates don’t get lost. Your site crew and back office know where things stand, and you stay in sync.

- It helps you stay compliant. In regulated industries, small misses can turn into big problems. When you schedule safety checks or maintenance through your work order lifecycles, you build compliance into your everyday operations.

- It reduces emergency repair costs. Emergency repairs typically cost 3 – 5 times more than planned maintenance, and by proactively managing work orders, you can minimize unexpected breakdowns

- It enhances asset reliability. Regularly scheduled maintenance through effective work order management ensures your equipment works well..

And the risks of poor work order management are real. In 2007, a neglected section of unused pipe led to a propane release and massive fire at the Valero McKee Refinery. The damage totaled over $50 million, and four people were injured. A frozen, cracked pipe (left connected for 15 years) was the root cause.

This accident shows that without a reliable work order system critical maintenance tasks can slip through the cracks, leading to costly consequences.

Key Steps of the Work Order Management Process

The previous section shows why having a clear and structured workflow is essential. A strong work order process gives your team clarity at every step, reducing downtime and costly mistakes.

Here’s how a typical process plays out, from the first request to the final report:

- Work Request Submission: A formal work request is submitted, detailing the maintenance or service task needed.

- Evaluation and Approval: The request is evaluated for accuracy, urgency, and relevance. Is the task valid? Can it be bundled with other jobs? Once approved, it’s greenlit to move forward.

- Work Order Creation: Now task descriptions, location info, required tools and parts, safety protocols come together into a structured work order. This becomes your team’s playbook for the job. (if you need a ready work order template, we have one free to use).

- Scheduling and Assignment: Tasks are scheduled, and responsibilities are assigned to appropriate personnel or service crews.

- Execution: With clear instructions and mobile access, the field team executes the job. Photos, checklists, and notes are captured on-site, creating real-time visibility into progress and quality.

- Completion and Review: Upon task completion, the work order is reviewed to ensure all activities meet quality and compliance standards.

- Documentation and Closure: Finally, the work order is closed, but the info lives on. Labor hours, materials used, task outcomes, even images are saved and archived for future reference or audit.

As you can see, this approach is standardized and clear. Its goal is to facilitate efficient task management and ensure a clear audit trail for all maintenance activities.

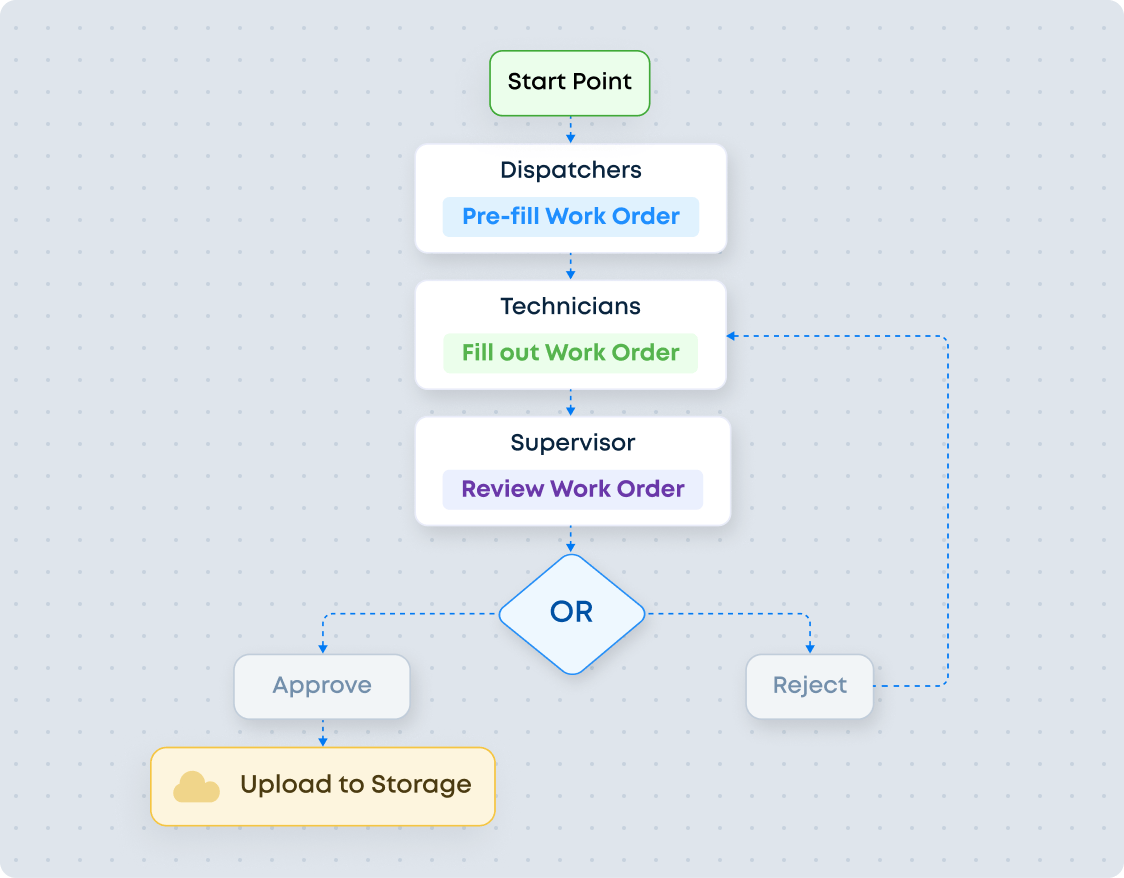

While it may be hard to track all the steps when on paper, with the proper software things get more straightforward. Take a look at this example of a flowchart mapping a basic work order process:

How to Optimize the Work Order Management Process

The following best practices help create a workflow that actually supports your team in the field:

- 1. Standardize Your Work Order Processes. You start by clearly defining the key stages of your work order lifecycle, from request submission to closure. Establish consistent procedures for each step, including approval workflows, documentation protocols, and follow-up reviews.

- 2. Build Workflows. Next, develop structured workflows for each type of task. This includes preventive maintenance, inspections, emergency repairs, and compliance checks. Workflows should outline what needs to happen, when, and by whom, enabling smoother transitions between stages. If you use specialized software, you can unite these flows into one single process.

- 3. Digitize Work Orders. Use mobile-friendly forms and checklists to ensure your field teams can access, update, and submit work orders directly from the jobsite even when offline. It’s always better to start this transition in advance as you may have to many (or too long) templates and it will take time.

- 4. Automate Task Assignments. Use assignment rules based on criteria like technician availability, location, or job type to ensure work is distributed efficiently and without delays.

- 5. Prioritize Work Orders. Learn to distinguish urgent jobs from non-critical ones. Categorizing tasks by urgency helps you ensure critical issues are addressed promptly.

- 6. Centralize Documentation. Ensure all work order data (job details, checklists, photos, materials used) is stored in a centralized system. This provides a single source of truth for everyone, supporting real-time visibility.

- 7. Train Personnel Regularly. Training programs that ensure everyone understands how to follow workflows and comply with documentation standards will make your admin life so much easier. Training should be ongoing and adapt to updates.

As a final step, make it a habit to review work order metrics consistently. A lot of software offers different kinds of reporting, so you may find out what’s included in your plan and how to use it.

Read More: Learn how Comfort Systems USA manages mobile work orders with workflow automation

Choosing the Right Work Order Management System for You

Choosing the right work order management system is an important step that will determine how your field teams work. The right platform can improve task execution from start to finish, while the poor choice can add you a headache.

Fluix is a field productivity platform that offers mobile-first work order management designed for industries like construction, energy, and aviation. Based on over a decade of experience supporting field work, here are the key features we recommend to look for when evaluating work order management software:

- Mobile Access with Offline Capability. For teams often working in environments with limited internet access, offline mode is a must to complete checklists, capture photos, and submit forms.

- Automation & Workflows. You need to be able to automate task assignments, notifications, and approvals as well as build workflows that reflect your operational needs.

- Ease of Use & Interface. A clean, intuitive interface that’s easy to learn for both tech-savvy users and those new to digital tools will give you faster user adoption.

- Task Progress Tracking. Monitoring the status of each work order in real-time improves visibility and accountability.

- Pilot Project. Those who are not ready to roll out a full system, can start with a small pilot project. Test the platform with a single crew or workflow, evaluate the results, and scale from there based on real-world feedback.

- Support & Implementation. You don’t want to be on your own when things get technical. For this, a straightforward onboarding process and customer success team available to help with setup, training, and customization will be crucial.

- Transparent Pricing. Cost matters, especially when scaling across multiple teams or sites. If the tool offers flexible pricing tailored to your business size and goals, you can grow your digital toolkit without stretching your budget.

As you see, choosing a work order system is a strategic decision. And Fluix is built for that job – designed with the field in mind, backed by a team that’s here to help you succeed.