What Is the Risk Assessment Process?

The risk assessment process involves spotting hazards in your workplace and evaluating how much danger they pose to your team. While some risks are small, others demand immediate action to keep workers safe.

Risk assessment isn’t a one-time task. It’s an ongoing, multi-step approach that must adapt to changes within your company.

Keeping the risk assessment process simple and straightforward helps minimize mistakes and improves compliance. When done right, risk assessment is a powerful tool for creating a safe environment for your team.

Why Is the Risk Assessment Process Needed?

When someone gets hurt at work, the impact ripples through the whole company—downtime, reduced productivity, lowered morale, and unexpected costs are just the beginning.

An effective risk assessment process helps prevent serious on-the-job injuries by identifying risks and reducing dangers. Here’s how else it benefits your team and operations:

- Stay Compliant with Safety Standards: Many industries enforce strict rules around handling hazardous materials. Regular assessments and safety audits help keep your company compliant and running smoothly.

- Use Resources Wisely: Every workplace has risks, but trying to tackle them all at once isn’t practical. The risk assessment procedure helps you zero in on the biggest hazards, so you’re directing resources where they can make the most difference.

- Improve Productivity and Reputation: Frequent assessments keep you on top of new hazards as your business changes. Reducing risks keeps productivity steady and shows your commitment to employee safety.

Basic Steps in the Risk Assessment Process

Risk assessment is a series of actions that together create a safer, more prepared workplace. Here are the five core risk assessment steps:

1. Identify Hazards

Begin the process by examining your work environment closely to spot potential hazards. Keep in mind that a hazard (like a wet floor) differs from a risk (the chance of someone slipping on that floor).

Common workplace hazards include:

- Toxic chemicals

- Unsafe work practices

- Machinery that could malfunction or be misused

2. Assess Risks

Not all hazards are equally risky. Think about the impact of each risk on daily operations and how often it might occur. This step helps you prioritize the biggest dangers. Consider factors like:

- How quickly the risk could affect operations

- Which employees are most exposed

- Existing safety measures in place

3. Control Risks

Choose the best actions to manage each hazard. Some risks can be handled by changing how tasks are done or by adding safety gear. For others, you might lower the risk by using safer materials or adjusting task schedules to reduce exposure.

4. Record Results

Document everything from your assessment. This record shows that you’re proactive about safety and should include metrics to track safety across your company.

Keeping a well-organized record helps you monitor the overall risk landscape and serves as a valuable reference point when new risks appear or circumstances change.

5. Keep an Eye on the Results

As your business grows, so will potential risks. Reassess and adjust your safety plans whenever you add new processes, materials, or team members. Flexibility in your risk assessment process keeps everyone safe, especially when change brings fresh challenges.

Transform Your Risk Assessment Process with Fluix: Start Automating Today

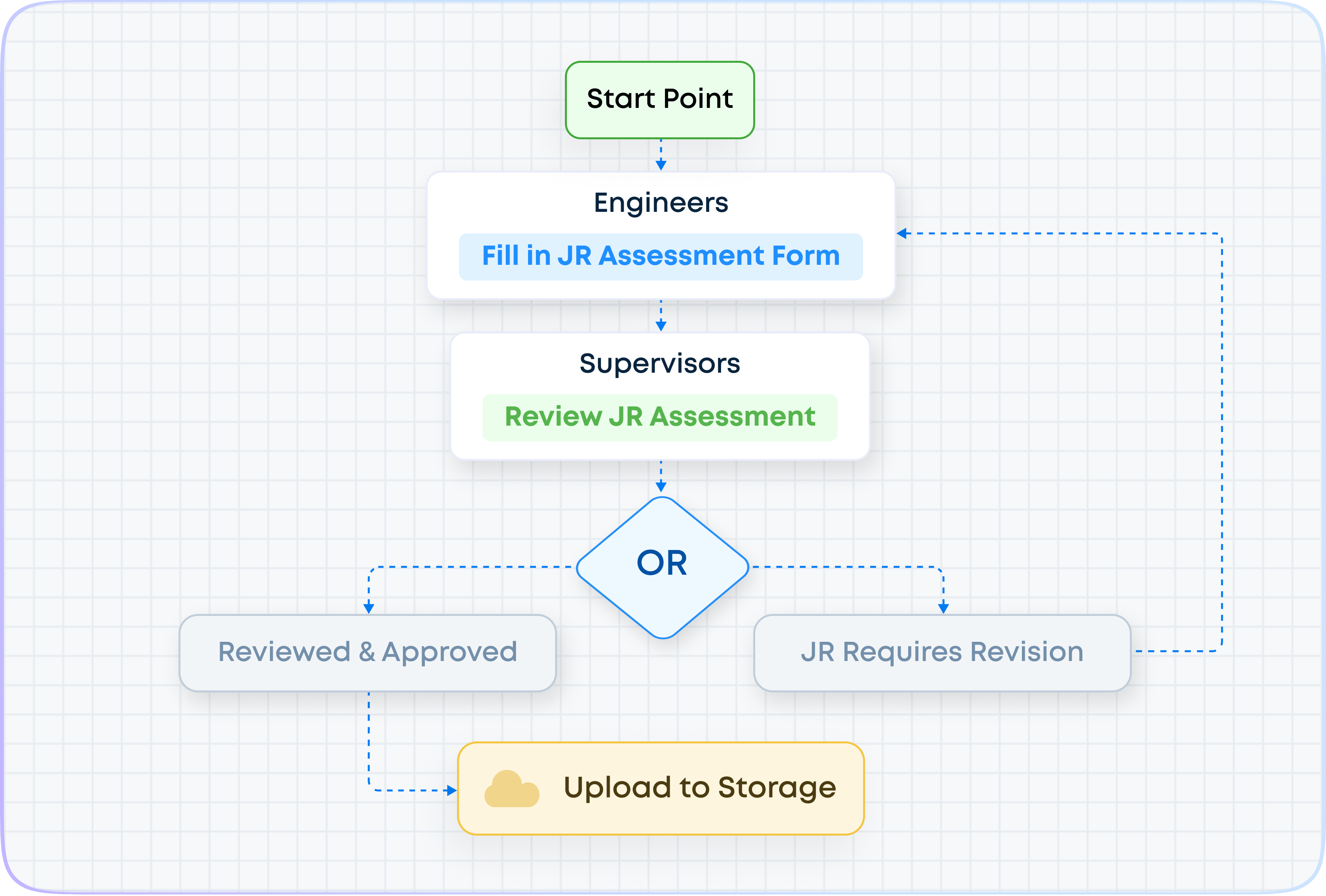

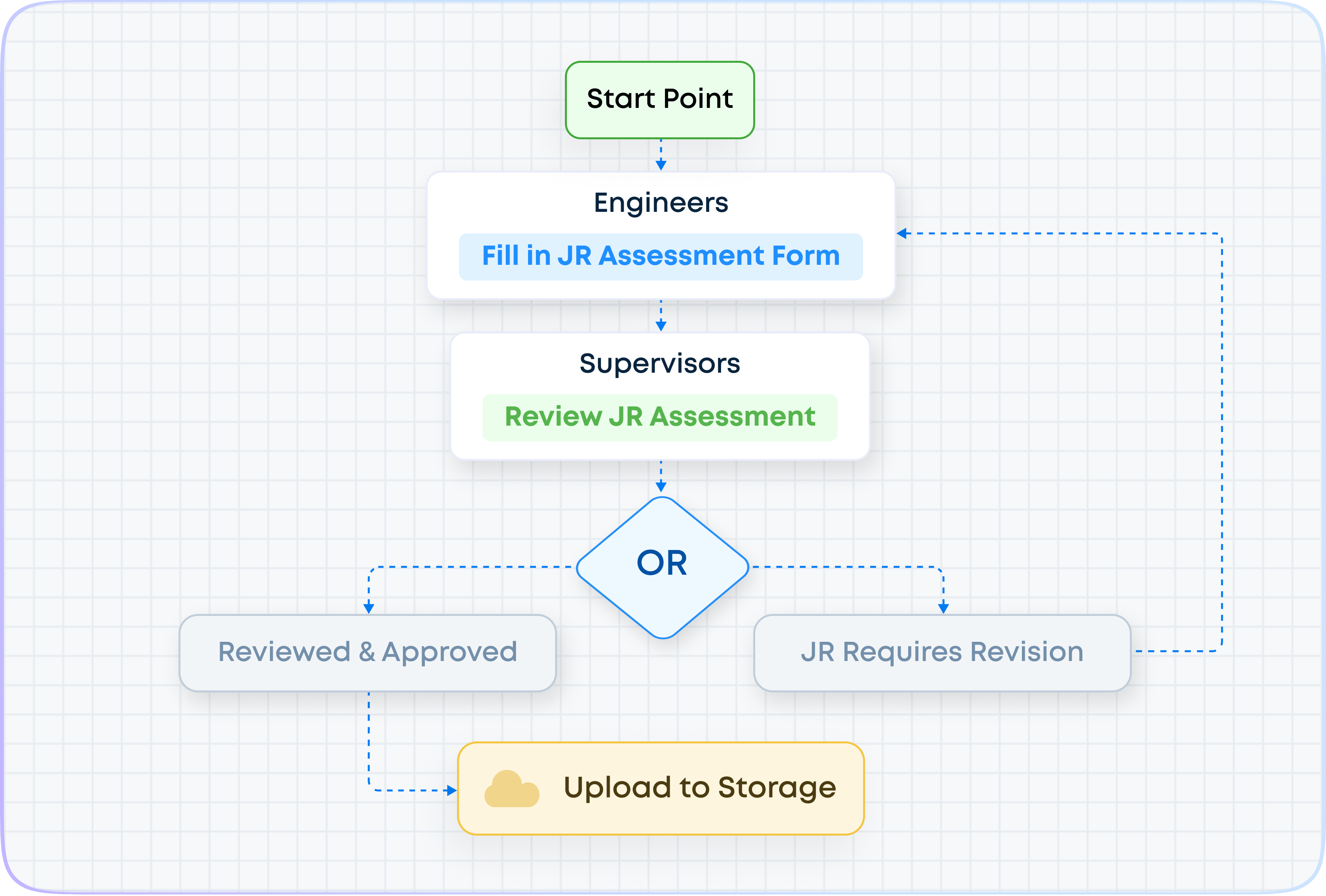

Risk Assessment Process Flowchart

Follow these steps in the right order to make sure your risk assessments are accurate and effective. Skipping steps or going out of order can lead to mistakes. Here’s the recommended risk assessment flow:

- Complete a risk assessment form

- Review multiple assessments to spot patterns and recurring risks

- Determine which hazards pose the highest risk

- Allocate resources to address each high-priority hazard

- Report on the effectiveness of each risk control method

- Regularly review findings and documents related to safety to know when updates are needed

To cover the key aspects of the process, we recommend using these checklists:

Challenges of Manual Risk Assessment

Manual risk assessment can quickly drain time and resources.

Whether you take it on yourself, or assign it to a team, manual processes pull time from other tasks. Completing each assessment, suggesting improvements, and communicating on safety to everyone involved takes time.

The paperwork can also pile up quickly, making it hard to keep track of everything and increasing the chances of human error. Without the right tools, important safety updates can get lost or delayed.

Human biases can also impact assessments. Personal experiences or assumptions may shape how a person evaluates a specific risk, potentially leading to inaccurate assessments. Objective tools and processes are essential for effective risk assessments.

How to Optimize the Risk Assessment Process

Here’s how to make your risk assessment process more reliable, proactive, and aligned with your team’s safety goals.

1. Standardize Your Templates

Create a standardized risk assessment template. This provides a reliable framework, ensuring that all assessments are consistent, thorough, and easy to review.

2. Leverage Digital Tools

Use software like Fluix that automates data entry and provides real-time access to risk assessments and updates. With instant access to information and approval workflows, your team can stay aligned and act on risk mitigation efforts more quickly.

3. Use Data to Guide Decisions

With your data centralized in digital tools, you can track trends from safety reports, near misses, and audits. This data-driven approach helps you anticipate issues, so you’re proactively managing risks rather than reacting to them.

4. Implement an Action Tracking System

Set up a centralized system to assign, document, and track corrective actions based on identified risks. This keeps everyone accountable and gives clear visibility into the progress of risk mitigation efforts.

5. Establish a Review Cycle

Create a regular review schedule, whether that’s every few months or whenever there’s a big change. This keeps your safety practices relevant and effective.

Managing Risk Assessment with Fluix

Here are six key features Fluix offers to simplify your risk assessment process:

- Automated workflows: Fluix automates repetitive tasks in the risk assessment process, such as data entry, approvals, and report generation.

- Centralized document management: Fluix safety management system software provides a secure, cloud-based platform for storing all risk assessment documents, including safety audits, incident reports, and control measures.

- Data-driven insights: Fluix’s data capabilities enable you to track safety metrics, analyze trends, and make informed decisions.

- Customizable templates: Fluix lets you create and tailor risk assessment templates to fit your specific needs, including fields for photo documentation, notes, and calculations.

- Real-time access and updates: With instant data syncing, Fluix keeps your entire team updated on the latest safety information. This also means everyone can create, view, and approve risk assessments from any device.

- Action tracking system: Fluix includes a centralized system to assign, track, and document corrective actions for identified risks.