Digitalization describes the deployment of digital technologies for smarter asset management. From monitoring systems for photovoltaic panels and solar equipment to the use of sensors to make more informed choices oriented towards peak power production, here are four ways that digitalization can optimize the operation of a solar farm.

Digitalization in the Decarbonization Energy Sector

Solar farm digitalization generally consists of sensors and connected systems that monitor asset performance. Here are a few measures that digitalization makes possible:

- Monitoring panel energy output: Using a monitoring and control system to monitor PV panel output can provide solar farm operators with the data needed for optimization. These systems can include sensors set up for remote monitoring.

- Measuring solar radiation: Pyranometers are used to measure solar irradiance on PV installations. These sensors feature thermopiles that can often produce proportional responses in less than 30 seconds.

- Tracking panel temperature: The efficiency of PV panels declines when this equipment becomes very hot. Temperature readings can guide panel placement and utilization.

- Factoring in wind speeds: Wind can cool solar panels, which can help optimize production. Solar panels cooled by 1 degree Celsius are 0.05 percent more efficient, and this increased efficiency can add up over time.

In addition to using a monitoring and control system, workflow automation software with code-free automation functionality can increase the level of control over solar farm operations. The ability to optimize power production and employee productivity at the same time can enable any solar power plant to generate more power and run more efficiently.

1. Monitor and Forecast Power Generation

Monitoring and control systems help solar farm operators make smarter decisions regarding panel placement, utilization, maintenance, and repair. These systems also enable operators to work based on better production forecasts, rendering systems more stable. More historical data allows for more accurate analytical and predictive models for seasonal production or generation during a wide variety of weather conditions.

Operators who have remote access to PV panel and electrical system data through monitoring and control systems can keep an eye on conditions and adjust panel production or tracking systems in real time. Workflow management and automation systems can work alongside solar farm monitoring and control systems to ensure that technicians provide maintenance on schedule and do repairs at times that minimize downtime during peak generation hours.

2. Pursue Data-Driven Solar Power Innovations

The availability of a wide variety of data points, such as sensor readings, with a monitoring control system is only as effective as the analytical approaches that are taken to better understand and act on this information. Operators that prioritize accurate and relevant data about solar farm performance tend to run more productive farms than operators who are intimidated by or are otherwise hesitant to act on specialized solar energy system data.

Workflow management solutions can provide comparable granular data for optimizing the productivity of technicians and other solar farm professionals. When technicians are notified of scheduled repairs in workflows or when processes are set up to support the timely maintenance, repair, or replacement of PV panels and electrical equipment, employee operations at a solar farm can also become more efficient.

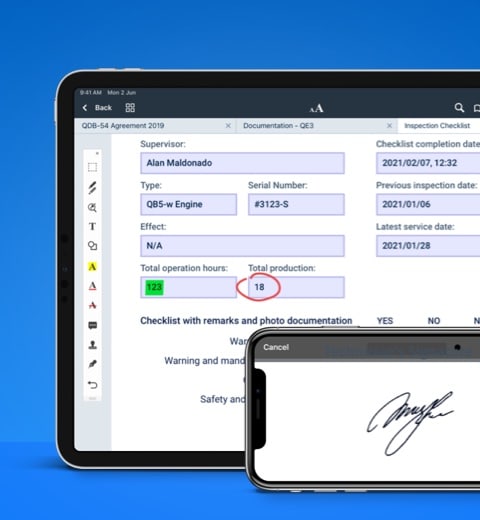

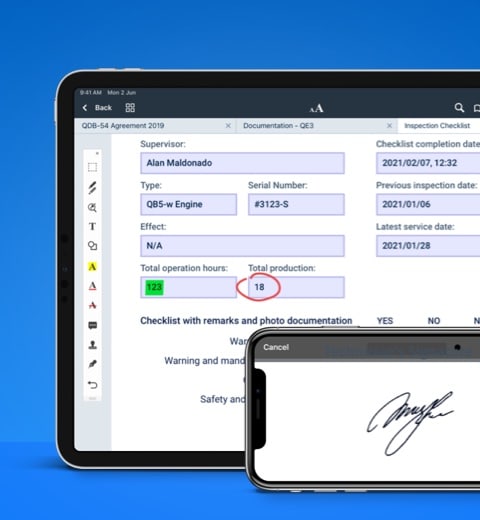

Field Data Collection for Renewable Energy

See how your solar farm teams can perform mobile inspections using digital checklists and mobile devices, and send them for review and approval in several taps.

3. Model Optimum Performance With Digital Twin Technology

Digital twin technology is a recent trend across many industries, ranging from renewables to construction and manufacturing. A digital twin is a virtual replica of a solar farm based on normal operative data that can be used to simulate performance under optimal working conditions.

Solar farm operators can benefit from being able to compare real-time asset performance with an ideal standard. The data made available by monitoring and control systems undergirds this approach to asset performance management, and a comparison of the digital twin output with the operational farm can identify needed equipment maintenance or opportunities to optimize workflows.

4. Implement Digital Checklists for Maintenance and Repairs

Checklists are a relatively simple way to make technicians’ jobs easier. Rather than tasking technicians with recalling best practices for handling equipment and the measures necessary to meet any relevant regulatory requirements, checklists can remind workers of these and other important considerations during the following tasks and processes:

- Panel inspections and maintenance: A checklist for panel inspections might ask technicians to check panel surfaces for soiling, which reduces energy output. Uneven soiling can also lead to localized hot-spot failures, which may be prevented by scheduled or condition-based cleaning.

- Electrical system service: Any alternating or direct current components used in solar farm equipment may require maintenance or repairs. Common wire management issues include wires that are broken or out of place and loose connections.

- Inverter maintenance or repair: Whether a solar farm relies on a central, string, DC-optimized, or micro-inverter configuration, inverters are important components that should be serviced periodically, and repaired or replaced as needed. Checklists can be used to guide technicians through lockout/tagout and other important safety procedures.

- Ground management: Solar farms that have ground-mounted panels often require vegetation management, snow removal, and erosion controls. The landscape and layout of a solar farm will determine the frequency and nature of these maintenance measures.

Fluix workflow management software supports digital checklists that technicians can fill out in the field on compatible iOS or Android mobile devices. Offline access can make it easier for operators to manage remote solar farms.

Digitalization and the Future of Energy

The most significant steps that solar farm operators can take to reap the benefits of digitalization include implementing and properly calibrating a monitoring and control system and workflow management solution. Fluix can be used alongside most solar farm monitoring and control systems to enable stakeholders, operators, and technicians to protect and optimize the productivity of these assets.

These four methods can significantly increase the production of a solar farm. Comparing sensor readings and output ratings with optimal models can point stakeholders towards areas for improvement or equipment upgrades.

Remote monitoring also reduces the frequency of hands-on inspections. Solar farm operators can use Fluix to digitalize and automate workflows and an equipment monitoring and control system to achieve optimal power generation.