In the wind energy sector, where technicians deal with high-voltage systems, and rotating blades, the stakes are high, and solid safety procedures are a must.

For techs in the field, a robust lock out/tag out (LOTO) procedure is the first line of defense.

It includes clear checklists that keep your crew safe and your turbines turning. These checklists ensure hazardous energy is safely isolated before maintenance begins and reactivated without risk when the job’s done.

Contents:

What Is a Lock Out Tag Out (LOTO) Template?

A lock out tag out template is a checklist used by safety officers and managers who take the appropriate steps to isolate energy sources when servicing industrial equipment or heavy machinery.

Without a clear, enforceable, and easily accessible protocol for maintaining hazardous energy sources, your company is exposed to a spectrum of risks, including:

- Operational downtime costing thousands per hour

- OSHA fines, potentially exceeding $150,000 per willful or repeated violation

- Reputation damage makes securing permits, funding, and insurance harder

- Worker injuries or fatalities result in lawsuits and stalled projects

What’s Included in Your Lock Out Tag Out Form?

Your LOTO template includes the following:

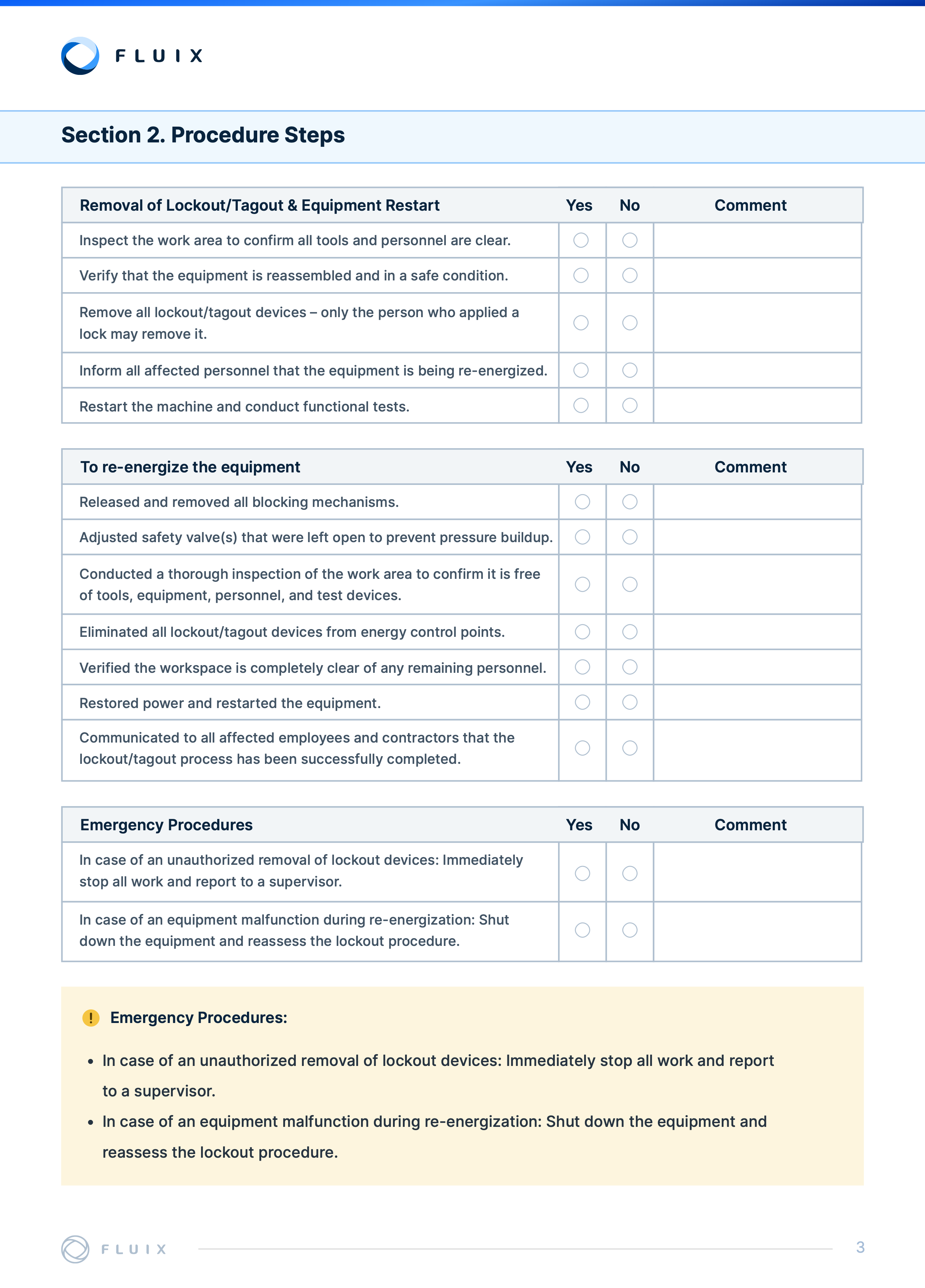

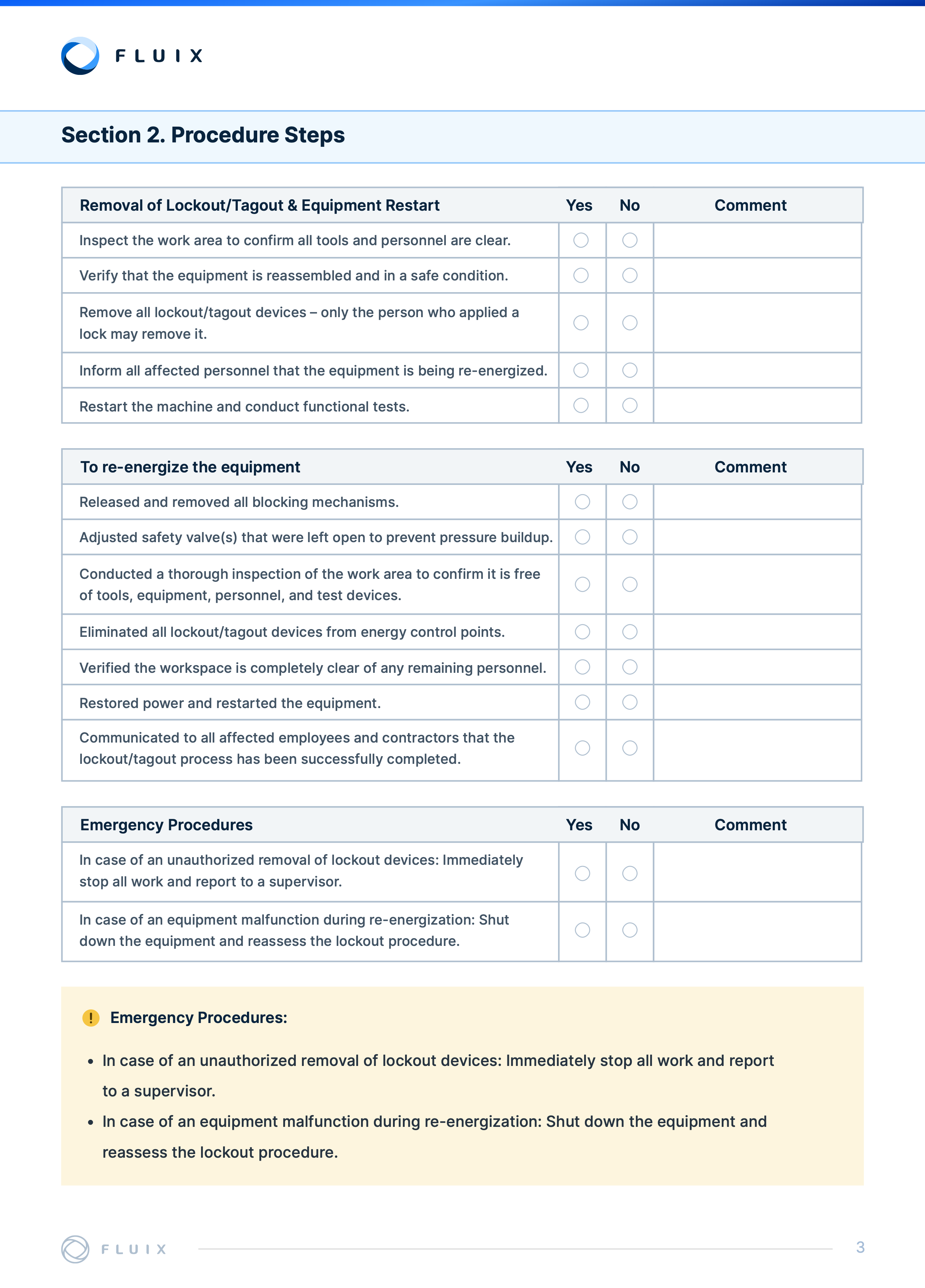

Equipment Lock Out Checklist

- Equipment details (name, number, location, department)

- Lock out date & personnel involved

- Authorization & required signatures (employee, supervisor, safety officer)

- Reason for lock out & removal process

Tag-Out Checklist

- Pre-lock out verification (equipment details, unit, department)

- Photo documentation of lock out placement

- Approval & verification signatures

- Tag-out removal authorization

This lock out tag out procedures template ensures that every technician follows industry best practices, reducing errors and enhancing operational efficiency.

Optimize Safety, Compliance, and Efficiency with Fluix

See how Fluix digital LOTO templates and automated workflows can streamline your wind turbine maintenance

How Fluix Helps Digitalize Lock Out Tag Out Forms

A traditional paper-based loto procedure template creates significant safety and efficiency challenges, such as delayed approvals, misplaced forms, and incomplete documentation.

With Fluix’s software for safety management, field teams can confidently access LOTO forms from any device and complete a lock out tag out form on-site.

- Access digital lock out tag out procedure checklist from any device: Fill out and complete digital lock out tag out forms and checklists on mobile devices from remote sites

- Automate approval workflows: Supervisors receive instant notifications when LOTO processes need review to reduce downtime

- Ensure OSHA compliance: Every step is time-stamped and securely recorded, making audits easier

- Enable offline functionality: Teams can complete checklists without internet access and rely on automatic syncing once online.

Digitizing your LOTO processes will help you minimize downtime, prevent safety hazards, and ensure compliance with industry regulations.